EN24 is a high strength steel alloy that is also known as 4340. It is supplied, tempered, and hardened. It is popular and widely used due to its excellent strength in numerous components, including bolts, gears, and studs. Other grades can be surfaced-hardened to create parts with improved water resistance through nitriding or induction.

EN24 is generally supplied in a final heat-treated condition. It is a popular grade of through-hardening alloy steel, which is also machinable in the “T” condition. EN24 is best-suited for use in heavy-duty commercial shafts, axles, and other components. The steel alloy can maintain good impact value at even lower temperatures, so it is frequently used for offshore applications.

The strength of EN24 is excellent. It is a combination of nickel-chromium-molybdenum and offers incredible tensile strength with excellent ductility and resistance to water. It performs well for use at higher temperatures as well. EN24 is a suitable material that treats quickly and is supplied already tempered.

As a standard high-speed steel grade, EN24 is a well-balanced alloy composition. It forms the basis of durability, edge retention, and rendering. It is perfect for a wide variety of applications that require flexibility.

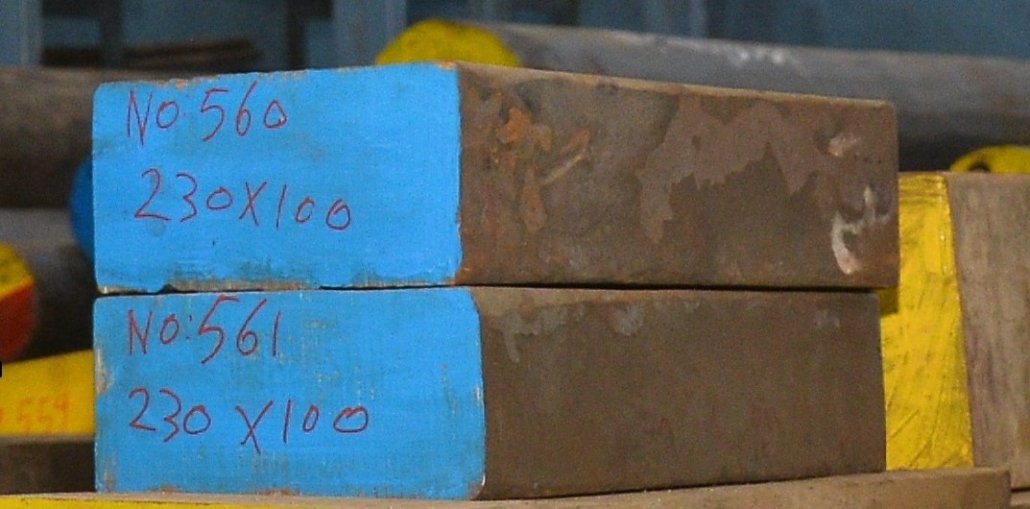

Available Types & Range

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ 16 -Φ 140 | Standard or As your request |

| Forged Rounds | Φ 140 – Φ 650 | Standard or As your request |

| Forged Flats | Thickness : 65 – 450 Width: 130 – 650 |

Standard or As your request |

EN – 24 ROLLED ROUNDS

6 mm to 150 mm Dia

Brand – , LSRM,JAILAXMI, KISCO

EN 24 – FORGED ROUND

Size – 130 mm to 670 mm Dia

Brand – Kolkatta& Punjab Main Make

EN 24 FORGED FLATS

Width – 65 -650 mm

Thickness – 65 mm to 450 mm

Brand – Kolkatta& Punjab Main Make

Chemical Composition & Technical Specification EN 24

Element |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Ni |

Content (%) |

0.36-0.44 |

0.10-0.35 |

0.45-0.70 |

0.035 Max |

0.040 Max |

1.00-1.40 |

0.20-0.35 |

1.30-1.70 |

EN24 Mechanical Properties:

Condition |

TensileN/mm² |

YieldN/mm² |

Elongation% |

IzodKCV J |

HardnessBrinell |

T |

850-1000 |

650 |

13 |

35 |

248-302 |

U |

925-1000 |

755 |

12 |

42 |

269-331 |

V |

1000-1150 |

850 |

12 |

42 |

293-352 |

W |

1075-1225 |

940 |

11 |

35 |

311-375 |

X |

1150-1300 |

1020 |

10 |

28 |

341-401 |

Y |

1225-1375 |

1095 |

10 |

21 |

363-429 |

Z |

1550 |

1235 |

5 |

9 |

444 |

Key features:

• Very high strength steel alloy

• Easy to heat treat and temper

• Supplied hardened & tempered

• Good combination of strength, ductility and wear resistance

Machinability

Readily machinable

Hardening

Supplied hardened and tempered.

Applications

• High strength shafts

• Punches & dies

• Drill bushings

• Retaining rings

• Gears